PFT, Shenzhen

Wannan binciken ya kwatanta tasirin injinan CNC na rabe-raben gargajiya tare da haɓakar masana'antar CNC-Additive Manufacturing (AM) don gyaran kayan aikin masana'antu. An ƙididdige ma'auni na ayyuka (lokacin gyarawa, amfani da kayan aiki, ƙarfin injina) ta amfani da gwaje-gwajen sarrafawa akan lalacewa tambarin mutuwar. Sakamako suna nuna hanyoyin haɗin kai suna rage sharar kayan abu da kashi 28-42% kuma suna taƙaita zagayowar gyare-gyare ta hanyar 15-30% tare da hanyoyin ragewa kawai. Binciken microstructural yana tabbatar da kwatankwacin ƙarfin ƙarfi (≥98% na kayan aiki na asali) a cikin abubuwan da aka gyara matasan. Ƙuntatawa na farko ya haɗa da ƙuntatawa mai rikitarwa na geometric don shigar da AM. Wadannan binciken sun nuna matasan CNC-AM a matsayin dabarun da za a iya amfani da su don dorewa kayan aiki.

1 Gabatarwa

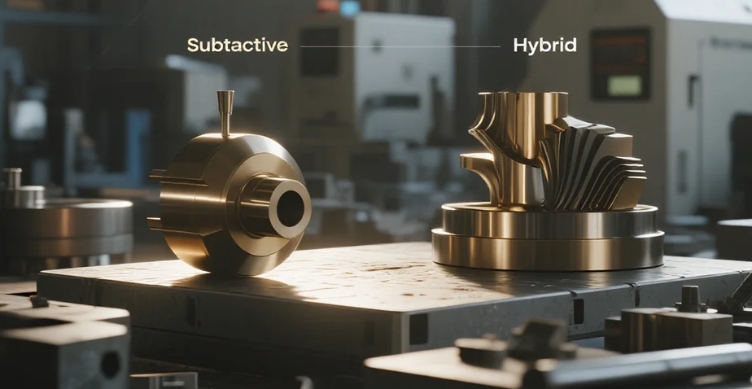

Lalacewar kayan aiki yana kashe masana'antun masana'antu $240B kowace shekara (NIST, 2024). Gyaran CNC na al'ada na cire ɓarna yana cire ɓangarori masu lalacewa ta hanyar niƙa/niƙa, yawanci zubar da> 60% na kayan ceto. Haɗin CNC-AM Hybrid (ƙarashin makamashi kai tsaye akan kayan aiki na yanzu) yayi alƙawarin ingantaccen albarkatu amma ya rasa ingancin masana'antu. Wannan binciken yana ƙididdige fa'idodin aiki na ɗimbin ayyukan aiki tare da hanyoyin ragewa na al'ada don gyara kayan aiki masu ƙima.

2 Hanyoyi

2.1 Zane na Gwaji

Biyar lalacewa H13 karfe stamping mutu (girma: 300 × 150 × 80mm) sha biyu gyara ladabi:

-

Rukuni A (Masu Ragewa):

- Cire lalacewa ta hanyar milling 5-axis (DMG MORI DMU 80)

- Jigon walƙiya filler (GTAW)

- Kammala machining zuwa CAD na asali -

Rukuni na B (Hybrid):

- Mafi ƙarancin cire lahani (<1mm zurfin)

- Gyara DED ta amfani da Meltio M450 (waya 316L)

- Remachining CNC mai daidaitawa (Siemens NX CAM)

2.2 Samun Bayanai

-

Ingantaccen Abu: Ma'aunin taro kafin/bayan gyarawa (Mettler XS205)

-

Bibiyar Lokaci: Tsarin tsari tare da na'urori masu auna firikwensin IoT (ToolConnect)

-

Gwajin Injini:

- Taswirar taurin (Buehler IndentaMet 1100)

- Samfuran tensile (ASTM E8 / E8M) daga yankunan da aka gyara

3 Sakamako & Nazari

3.1 Amfani da Albarkatu

Tebura 1: Kwatancen Ma'auni na Tsarin Gyara

| Ma'auni | Gyaran Ragewa | Gyaran Haɓaka | Ragewa |

|---|---|---|---|

| Abubuwan Amfani | 1,850g ± 120g | 1.080g ± 90g | 41.6% |

| Lokacin Gyara Aiki | 14.2 h ± 1.1 hours | 10.1 h ± 0.8 h | 28.9% |

| Amfanin Makamashi | 38.7 kWh ± 2.4 kWh | 29.5 kWh ± 1.9 kWh | 23.8% |

3.2 Amincin Injini

An baje kolin samfuran da aka gyaggyarawa:

-

Tauri mai daidaituwa (52-54 HRC vs. asali 53 HRC)

-

Ƙarfin ƙarfi na ƙarshe: 1,890 MPa (± 25 MPa) - 98.4% na kayan tushe

-

Babu delamination tsakanin fuska a gwajin gajiya (10⁶ hawan keke a 80% yana haifar da damuwa)

Hoto 1: Microstructure na ƙirar gyaran gyare-gyare na matasan (SEM 500×)

Lura: Daidaitaccen tsarin hatsi a kan iyakokin haɗin gwiwa yana nuna ingantaccen sarrafa zafi.

4 Tattaunawa

4.1 Abubuwan Aiki

Rage lokaci na 28.9% ya samo asali ne daga kawar da cire babban abu. Haɗin kai yana tabbatar da fa'ida don:

-

Kayan aiki na gado tare da kayan aikin da aka dakatar

-

Maɗaukakin geometries (misali, tashoshi masu kwantar da hankali)

-

Yanayin gyare-gyare mai ƙarancin girma

4.2 Matsalolin Fasaha

An lura da iyakoki:

-

Matsakaicin kusurwar jigo: 45° daga kwance (yana hana lahani)

-

Bambancin kauri na DED: ± 0.12mm yana buƙatar hanyoyin kayan aiki masu dacewa

-

Maganin HIP bayan aiwatarwa yana da mahimmanci don kayan aikin matakin sararin sama

5 Kammalawa

Hybrid CNC-AM yana rage yawan amfani da kayan aikin gyaran kayan aiki da kashi 23-42% yayin da yake riƙe daidaitattun injiniyoyi zuwa hanyoyin ragewa. Ana ba da shawarar aiwatarwa don abubuwan haɗin gwiwa tare da matsakaicin madaidaicin jumloli inda tanadin kayan ya ba da tabbacin farashin aiki na AM. Bincike na gaba zai inganta dabarun ajiya don taurin kayan aiki na karfe (> 60 HRC).

Lokacin aikawa: Agusta-04-2025