Magnetic vs Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Aluminum

Marubuci: PFT, Shenzhen

Abstract

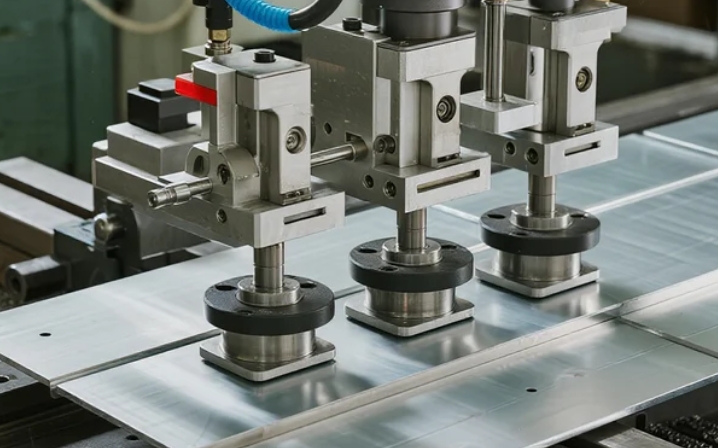

Madaidaicin mashin ɗin aluminum na bakin ciki (<3mm) yana fuskantar ƙalubale na aiki. Wannan binciken yana kwatanta tsarin maganadisu da huhu a ƙarƙashin yanayin niƙa CNC mai sarrafawa. Siffofin gwaji sun haɗa da daidaiton ƙarfi, kwanciyar hankali na thermal (20°C–80°C), jijjiga jijjiga, da murgudawar ƙasa. Pneumatic vacuum chucks kiyaye 0.02mm flatness don 0.8mm zanen gado amma da bukatar m rufe saman. Matsalolin lantarki sun ba da damar isa ga axis 5 da rage lokacin saitin da kashi 60%, duk da haka jawo igiyoyin ruwa sun haifar da dumama cikin gida sama da 45°C a 15,000 RPM. Sakamako suna nuna tsarin injin injin yana haɓaka ƙarewar saman don zanen gado> 0.5mm, yayin da mafitacin maganadisu yana haɓaka sassauci don saurin samfur. Iyakoki sun haɗa da hanyoyin haɗaɗɗiyar hanyoyin da ba a gwada su ba da kuma madadin tushen mannewa.

1 Gabatarwa

Sirinkin zanen gadon aluminium masu ƙarfi masana'antu daga sararin samaniya (fatun fuselage) zuwa na'urorin lantarki (ƙirƙirar ruwan zafi). Amma duk da haka binciken masana'antu na 2025 ya nuna 42% na daidaitattun lahani sun samo asali ne daga motsin aikin aiki yayin injin. Makullin injina na al'ada galibi suna karkatar da zanen gadon ƙasa-1mm, yayin da hanyoyin tushen tef ba su da tsauri. Wannan binciken yana ƙididdige hanyoyin samar da ci-gaba guda biyu: chucks electromagnetic leveraging remanence control technology da pneumatic tsarin tare da Multi-zone vacuum control.

2 Hanyoyi

2.1 Zane na Gwaji

-

Materials: 6061-T6 aluminum zanen gado (0.5mm / 0.8mm / 1.2mm)

-

Kayan aiki:

-

MagneticGROB 4-axis electromagnetic Chuck (ƙarfin filin 0.8T)

-

Cutar huhu: SCHUNK vacuum farantin tare da 36-zone manifold

-

-

Gwaji: Flatness na saman (Laser interferometer), thermal Hoto (FLIR T540), nazarin girgiza (3-axis accelerometers)

2.2 Gwaji Protocol

-

Tsaya Tsaye: Auna juyewa ƙarƙashin ƙarfin 5N na gefe

-

Kekuna na thermal: Rikodin zafin zafin jiki yayin niƙa (Ø6mm ƙarshen niƙa, 12,000 RPM)

-

Rigidity mai ƙarfi: ƙididdige girman rawar jiki a mitoci masu ƙarfi (500-3000 Hz)

3 Sakamako da Nazari

3.1 Ayyukan Matsala

| Siga | Nauyin huhu (0.8mm) | Magnetic (0.8mm) |

|---|---|---|

| Matsakaici Karya | 0.02mm | 0.15mm |

| Lokacin Saita | 8.5 min | 3.2 min |

| Max Temp Tashi | 22°C | 48°C |

Hoto 1: Tsarukan Vacuum sun kiyaye <5μm bambancin saman yayin da ake niƙa fuska, yayin da ƙwanƙwasa magnetic ya nuna ɗaga gefen 0.12mm saboda haɓakar thermal.

3.2 Halayen Vibration

Pneumatic chucks attenuated jituwa ta 15dB a 2,200Hz - mai mahimmanci don kyakkyawan aiki na ƙarshe. Haɗin aikin Magnetic ya nuna girman 40% mafi girma a mitocin sa hannu na kayan aiki.

4 Tattaunawa

4.1 Kasuwancin Fasaha

-

Fa'idar Pneumatic: Maɗaukakin kwanciyar hankali na yanayin zafi da jijjiga jijjiga sun dace da aikace-aikacen haƙuri mai girma kamar sansanonin abubuwan gani.

-

Magnetic Edge: Sake daidaitawa cikin sauri yana goyan bayan yanayin shagunan aiki don sarrafa nau'ikan nau'ikan nau'ikan.

Iyakance: Gwaje-gwajen da ba a haɗa su da ruɓaɓɓen zanen gado ko mai mai inda ingancin injin ya ragu> 70%. Hanyoyin warware matsalar haɗin gwiwa suna ba da garantin nazari na gaba.

5 Kammalawa

Don bakin ciki aluminum sheet machining:

-

Haɗin aikin pneumatic yana ba da daidaito mafi girma don kauri> 0.5mm tare da filaye marasa daidaituwa.

-

Tsarin Magnetic yana rage lokacin yankewa da kashi 60% amma yana buƙatar dabarun sanyaya don sarrafa zafi

-

Mafi kyawun zaɓi ya dogara da buƙatun kayan aiki da buƙatun haƙuri

Ya kamata bincike na gaba ya binciko nau'ikan nau'ikan matsi da ƙarancin tsangwama da ƙira na lantarki.

Lokacin aikawa: Yuli-24-2025