Titanium's matalauta thermal watsin da high sinadaran reactivity sa shi yiwuwa ga surface lahani a lokacinInjin CNC. Duk da yake ana nazarin ilimin lissafi na kayan aiki da matakan yankan, haɓakawar sanyaya ya kasance mara amfani a aikin masana'antu. Wannan binciken (wanda aka gudanar a cikin 2025) yana magance wannan gibin ta hanyar ƙididdige yadda isar da saƙon da aka yi niyya ke inganta ƙimar ƙarewa ba tare da lalata kayan aiki ba.

Hanya

1. Gwaji Design

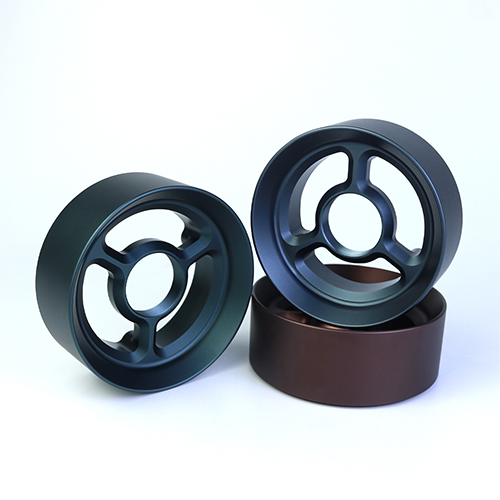

●Abu:Sandunan Ti-6Al-4V (Ø50mm)

●Kayan aiki:5-axis CNC tare da mai sanyaya kayan aiki (kewayon matsa lamba: 20-100 mashaya)

●Ana Bibiyar Ma'auni:

Rarraba saman (Ra) ta hanyar bayanin lamba

Cire kayan aikin flank ta amfani da hoton microscope na USB

Yanke zafin yankin (FLIR thermal camera)

2. Maimaituwar Gudanarwa

●Maimaikon gwaji guda uku a kowace saitin siga

● Ana maye gurbin abubuwan da aka saka kayan aiki bayan kowace gwaji

● Yanayin zafin jiki yana daidaitawa a 22 ° C ± 1 ° C

Sakamako & Bincike

1. Matsi mai sanyaya vs. Ƙarshen Sama

●Matsi (bar):2050 80

●Matsakaici Ra (μm) :3.2 2.1 1.4

●Kayan aiki (mm):0.28 0.19 0.12

Babban mai sanyaya matsa lamba (masha 80) ya rage Ra da 56% sabanin tushe (masha 20).

2. Tasirin Matsayin Nozzle

Nozzles masu kusurwa (15° zuwa tukwici na kayan aiki) sun fi ƙarfin saitin radial ta:

● Rage tarin zafi da 27% (bayanin zafi)

● Tsawaita rayuwar kayan aiki da kashi 30 (ma'aunin sawa)

Tattaunawa

1. Key Mechanisms

●Fitar Chip:Babban mai sanyaya matsa lamba yana karya dogon guntu, yana hana sake yankewa.

●Kula da thermal:Sanyaya wuri yana rage girman murdiya.

2. Iyakokin Aiki

● Yana buƙatar gyarawar saitin CNC (mafi ƙarancin 50 bar famfo)

● Ba shi da tsada don samar da ƙananan ƙira

Kammalawa

Inganta matsa lamba na coolant da bututun ƙarfe jeri muhimmanci inganta titanium surface gama. Ya kamata masana'antun su ba da fifiko:

● Haɓakawa zuwa ≥80 mashaya sanyaya tsarin

● Gudanar da gwaje-gwajen saka bututun ƙarfe don takamaiman kayan aiki

Ya kamata ƙarin bincike ya bincika yanayin sanyaya (misali, cryogenic + MQL) don gauraye masu wuyar injin.

Lokacin aikawa: Agusta-01-2025