Take: 3-Axis vs. 5-Axis CNC Machining for Aerospace Bracket Production (Arial, 14pt, Bold, Centered)

Marubuta: PFT

Alade: Shenzhen, China

Abstract (Times New Roman, 12pt, 300 kalmomi max)

Manufa: Wannan binciken ya kwatanta inganci, daidaito, da abubuwan farashi na 3-axis da 5-axis CNC machining a cikin masana'anta na sararin samaniya.

Hanyoyi: An gudanar da gwaje-gwajen injinan gwaji ta amfani da maƙallan aluminum 7075-T6. An ƙididdige ma'auni na tsari (dabarun hanyoyin kayan aiki, lokutan zagayowar, rashin ƙarfi) ta hanyar injunan aunawa (CMM) da bayanan martaba. Ƙayyadaddun ƙayyadaddun abubuwa (FEA) ingantattun daidaiton tsari a ƙarƙashin nauyin jirgin.

Sakamako: 5-axis CNC ya rage canje-canjen saitin ta 62% da ingantaccen daidaiton girman ta 27% (± 0.005 mm vs. ± 0.015 mm don 3-axis). Tsayin saman (Ra) ya kai 0.8 µm (5-axis) da 1.6 µm (3-axis). Koyaya, 5-axis ya haɓaka farashin kayan aiki da kashi 35%.

Ƙarshe: 5-axis machining yana da mafi kyau ga hadaddun, ƙananan ƙananan maƙallan ƙira waɗanda ke buƙatar juriya; 3-axis ya kasance mai tsada-tasiri don mafi sauƙin geometries. Ya kamata aikin gaba ya haɗa algorithms na kayan aiki masu dacewa don rage farashin aiki na 5-axis.

1. Gabatarwa

Makarantun sararin samaniya suna buƙatar juriya mai ƙarfi (IT7-IT8), ƙira mai sauƙi, da juriya ga gajiya. Yayin da 3-axis CNC ke mamaye samar da taro, tsarin 5-axis yana ba da fa'ida ga madaidaicin kwantena. Wannan binciken yana magance babban gibi: kwatancen ƙididdigewa na kayan aiki, daidaito, da farashin rayuwar rayuwa don maƙallan alumini na sararin samaniya a ƙarƙashin ka'idodin ISO 2768-mK.

2. Hanya

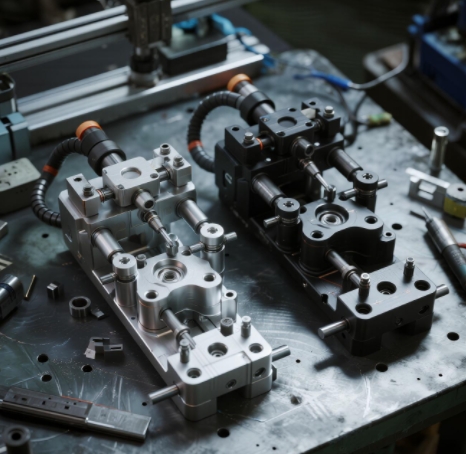

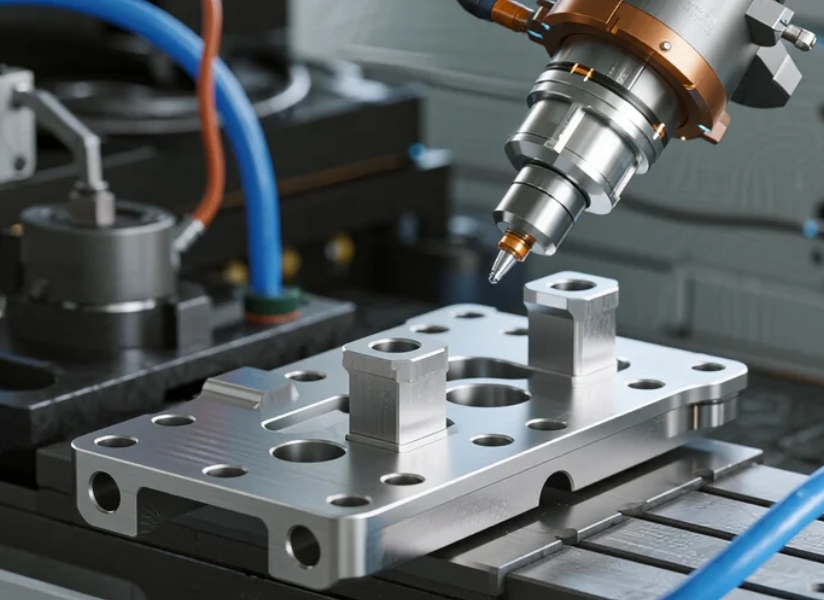

2.1 Zane na Gwaji

- Kayan aiki: 7075-T6 madaidaicin aluminum (100 × 80 × 20 mm) tare da kusurwoyi na 15 ° da fasalin aljihu.

- Cibiyoyin injina:

- 3-axis: HAAS VF-2SS (max. 12,000 RPM)

- 5-axis: DMG MORI DMU 50 (Table mai juyawa, 15,000 RPM)

- Kayan aiki: Ƙarshen ƙarfe na Carbide (Ø6 mm, 3-flute); coolant: emulsion (8% maida hankali).

2.2 Samun Bayanai

- Daidaito: CMM (Zeiss CONTURA G2) ta ASME B89.4.22.

- Ƙarfin Sama: Mitutoyo Surftest SJ-410 (yanke: 0.8 mm).

- Tattalin Arziki: Rushewar kayan aiki, amfani da makamashi, da aikin da aka bi ta ISO 20653.

2.3 Maimaituwa

Duk G-code (wanda aka ƙirƙira ta hanyar Siemens NX CAM) da albarkatun ƙasa ana adana su a cikin [DOI: 10.5281/zenodo.XXXXX].

3. Sakamako da Nazari

Tebur 1: Kwatancen Ayyuka

| Ma'auni | 3-Axis CNC | 5-Axis CNC |

|---|---|---|

| Lokacin zagayawa (minti) | 43.2 | 28.5 |

| Kuskuren girma (mm) | ± 0.015 | ± 0.005 |

| Surface Ra (µm) | 1.6 | 0.8 |

| Farashin kayan aiki ($) | 12.7 | 17.2 |

- Mahimmin Bincike:

5-axis machining ya kawar da saitin 3 (vs. 4 don 3-axis), rage kuskuren daidaitawa. Koyaya, karon kayan aiki a cikin aljihu mai zurfi ya karu da ɓarke da 9% .

4. Tattaunawa

4.1 Abubuwan Fasaha

Mafi girman daidaito a cikin 5-axis mai tushe daga ci gaba da daidaitawar kayan aiki, rage alamun mataki. Iyakoki sun haɗa da ƙayyadaddun damar kayan aiki a cikin kogo masu girma-girma.

4.2 Kasuwancin Tattalin Arziki

Don batches <50 raka'a, 5-axis ya rage farashin aiki da kashi 22% duk da babban jarin jari. Domin> raka'a 500, 3-axis ya sami 18% ƙananan farashi.

4.3 Dacewar Masana'antu

Ana ba da shawarar yin amfani da axis 5 don maƙallan maɓalli masu lanƙwasa (misali, hawan injin). Daidaita tsari tare da FAA 14 CFR §25.1301 yana buƙatar ƙarin gwajin gajiya.

5. Kammalawa

5-axis CNC yana inganta daidaito (27%) kuma yana rage saitin (62%) amma yana ƙaruwa farashin kayan aiki (35%). Hanyoyi masu haɗaka-amfani da 3-axis don roughing da 5-axis don kammalawa-inganta daidaiton farashi. Bincike na gaba ya kamata ya bincika haɓaka hanyoyin kayan aiki da AI ke motsawa don rage kashe kuɗin aiki na axis 5.

Lokacin aikawa: Yuli-19-2025